Session Summary: How Vyaire uses AWS analytics to scale ventilator production & save lives #ANT302 #reinvent

This post is the session report about ANT302: How Vyaire uses AWS analytics to scale ventilator production & save lives at AWS re:Invent 2020.

日本語版はこちらから。

Abstract

When COVID-19 hit the US, Vyaire Medical, one of the country’s only ventilator manufacturers, knew it would have to scale rapidly while still offering quality machinery. In order to scale to 20 times more than its usual production and gain insights from all its new data, Vyaire invested in an insights team to focus on the company’s analytics and machine learning. In this session, hear from Vyaire’s enterprise data management leader, Gopal Ramamurthi, about how the company leverages its AWS architecture, including Amazon Redshift, Amazon Elasticsearch Service, Amazon QuickSight, and more, to enable its business to have readily available data so it can make livesaving decisions.

Speakers

- Josh Kahn

- AWS Speaker

- Gopal Ramamurthi

- Enterprise Data Management Leader, Vyaire Medical

How Vyaire uses AWS analytics to scale ventilator production & save lives - AWS re:Invent 2020

Content

- What is Vyaire; our background

- AWS journey

- Building an integrated analytics platform

- COVID-19 forced a rethink of supply chain and our business

- Impact of data-driven decision-making

- Our next steps

What is Vyaire; our background

- Vyaire is a privately-held med devices manufacturing company

- Focus on respiratory care which is a sensitive life-saving device

- Occurred from Becton Dickinson

- Owned by Apax

- A conglomeration of multiple smaller units

- -> Comes with a lot of complexity

- We provide breathing solutions

- Ventilation

- Airway management

- Operative care

- Offer 27,000+ products across diagnosis, treatment, and monitoring

AWS journey

- The reason why Vyaire choose AWS

- AWS's analytics services and Integration services

- Vyaire needs to bring their dispersed systems together

- Q1 2019

- Journey to AWS begins

- Migrate on-premises workloads

- Q2 / Q3 2019

- Project Insight launched

- Focus on single source of truth for analytics

- People get and trust the data

- Project Insight launched

- Q4 2019

- 55% of on-premises workloads migrated

- Integrated 9 ERP systems in budding data lake

- Q1 / Q2 2020

- COVID-19 impact

- Insight Portal went live

- Migrated ventilator manufacturing applications to AWS

- Roll out analytics for the entire enterprise

- How do they increase adaption for analytics in a sudden shift

- Today

- Ventilator production scaled 20x (from 2019)

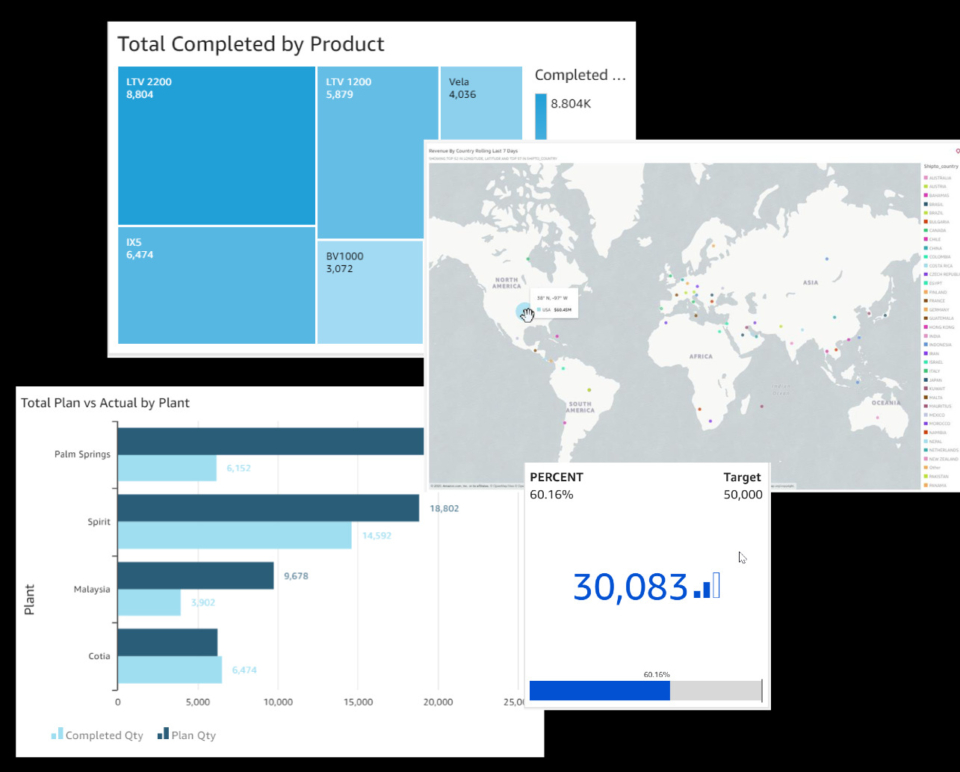

- 25 Amazon QuickSight dashboards

- More than 500 QuickSight users

Building an integrated analytics platform

- Project Insight enabled our response to COVID-19

- Rewind to 2018

- Company composed of multiple acquisitions, each with own backend systems

- No centralized enterprise data warehouse

- Production was managed via manual updates to Excel spreadsheets and 12 ERP systems

- Project Insight focused on need for consistent analytics and reporting

- AWS provided foundation

- Interoperability was a driving factor in selecting our AWS tool set

- Enables storage, analytics, and reporting

- Rewind to 2018

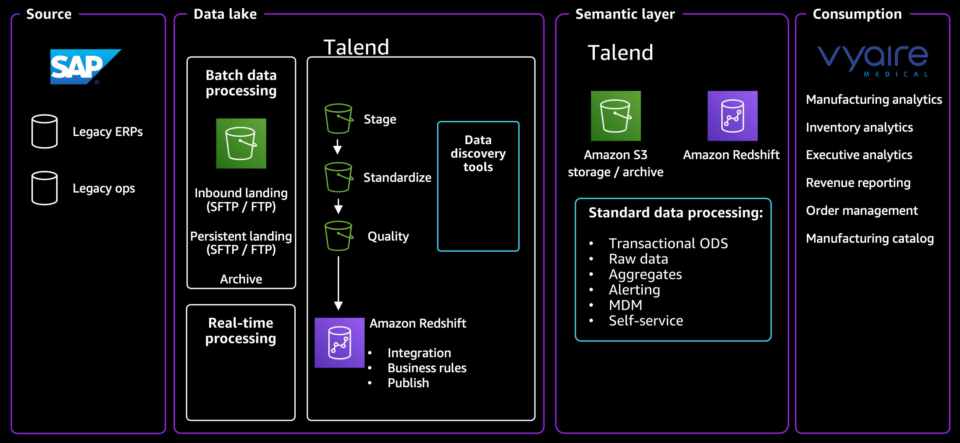

- Vyaire insights conceptual design

- Enabling capability for data analysis and consumption

- Four layer architecture;

- Source system

- Processing layer (Data lake)

- Gather information from swamp sources

- Bring the information consolidated in one platform

- Make sure it can have a good interoperability and it is economical and capturable all around the world

- Align different data formats to a cleansed, standardized format

- Semantic layer

- Keep it open, fluid and dynamic

- Consumption layer (Visualization)

- Fixed portal which is called Insight

- Abstracted layer for end users

- Five to Six different reporting tools

- Agility, flexibility, Scaling up and down are mandatory

- To make it more cloud-native

- Selecting AWS analytics services

- In some areas, the performance is a little short, but going all in AWS will reap a good benefit

- Amazon Redshift

- High-performance, scalable

- Testing proven performance relative to competing solutions

- Track record of growth and innovation

- Platform integration

- Cost-effective

- Amazon QuickSight

- Deeply integrated with AWS services: Amazon S3 and Amazon Redshift

- Create and scale in minutes

- Flexible

- Rich roadmap

- Cost-effective, lowest TCO

- Amazon ES

- Direct search and analytics from the Insight portal

- Low-maintenance, fully managed by AWS

- Performant

- AWS-assisted on best practices and tuning

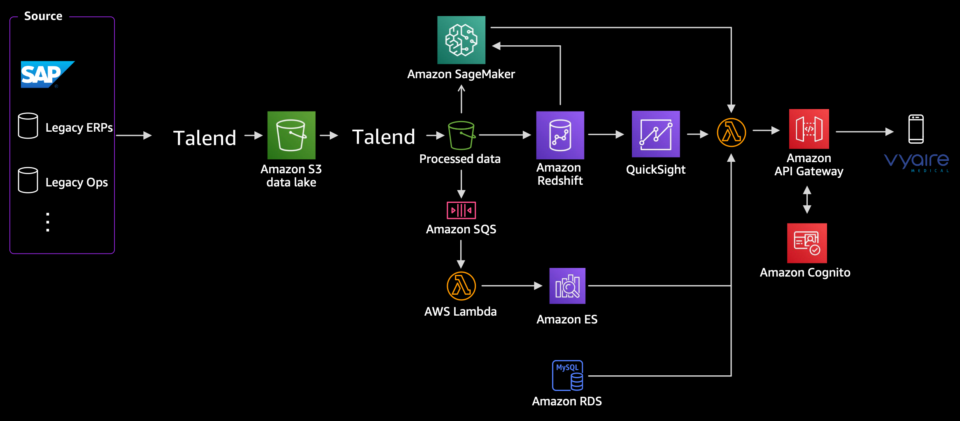

- Vyaire insights architecture

- Ingest the data from source systems into data lake

- Use Talend as the ingestion platform

- Amazon S3 data lake

- Cleanse the data swamp and write it back to the lake

- Semantic layer in Amazon Redshift

- Make data ready for consumptions

- Not too much layered for future changes

- Insight portal with a serverless architecture

- AWS Lambda excusetes the core logic

- The website hosted on Amazon S3

- Frontend is written in React Native

- View dashboards on QuickSight mobile

COVID-19 forced a rethink of supply chain and our business

- 20x increase in order volume from before COVID-19

- Suddenly the thought process completely changed

- 750/day target ventilator throughput, from 6/day pre-COVID-19

- Had to scale up the production

- It was a positive thing from the sales perspective

- But it's all about saving lives because there were thousands of lives out there

- From the operation standpoint, the factories can't scale up so much

- Spirit, a joint venture which is known for aero manufacturing

- Ramp up a factory within a matter of days and weeks

- -> Analytics services enabled them to come into play

- Photos: the Spirit manufacturing facilities

- Hundreds and thousands of people are sitting in the line

- Turned just a warehouse into the ventilation factory

Impact of data-driven decision-making

- Vyaire insights revolutionized decision-making

- View of global supply chain

- Enable fulfillment of 60,000 ventilators in 3 months

- Daily executive briefing, including:

- Production plan

- Helped the supply chain team to come up with a massive production plan which is constantly changing every couple of hours

- Yield analytics

- Understand not only what is the throughput, but also where is the problem by getting down into the details

- Global production and shipment

- Inventory tracking

- Daily production review

- Production plan

- Machine learning improved testing efficiency

- ML reduced number of reworked units by 40% prior to final testing

- Ventilators are tested over several stages before completion

- 73% of ventilator units were failing first pass of final testing

- Using SageMaker, able to predict unit failure before starting final testing

- Based on measurements of vent and historical results, tracked by serial number

- Predicts efficacy and confidence rate to pass

- Reduced first pass failure by 60%

Our next steps

- AWS Glue

- Migrating data preparation to AWS Glue from Talend

- Highly flexible, only runs when needed

- Lower TCO, easier to maintain

- Launching to production in January 2021

- Amazon SageMaker

- Extending machine learning to forecasting

- Leverage sales history obtained from insights

- Better predict needs for consumables

- Utilize data from AWS Data Exchange to extend proprietary data

We are now truly data-driven, from what was chaos before.

by Ed Rybicki, CIO Vyaire

AWS re:Invent 2020 is being held now!

You wanna watch the whole session? Let's jump in and sign up AWS re:Invent 2020!